Brij Advantage FrontSheets - Brij Encapsulants (India)

Brij Advantage FrontSheets

A solar module though looks simple, is a combination of highly engineered materials working in tandem to harness energy. One such component is the Ethylene Vinyl Acetate (EVA) encapsulant. This transparent layer of plastomer forms a protective layer over and under the solar cells preventing water, dirt and other external impurities from contaminating the cells and at the same time ensures optical transmissivity and electrical isolation. These encapsulants ensure that the module can be used outdoors for over 25 years without significant degradation.

With over 50,000+ hours of real environmental testing and over 200 MW of module laminations, ‘Brij Advantage’ series of module encapsulation solutions have been serving the industry since 2011. Optimised for hot and humid conditions at its ultra modern & fully automated production facility, ‘Brij Encapsulants’ offer lower failure rates, better performance and slower degradation during module lifetime, providing better overall return on investments. With separate quality assurance team performing regular in-line quality checks, Brij assures that your modules will last not for 25 years but for a lifetime.

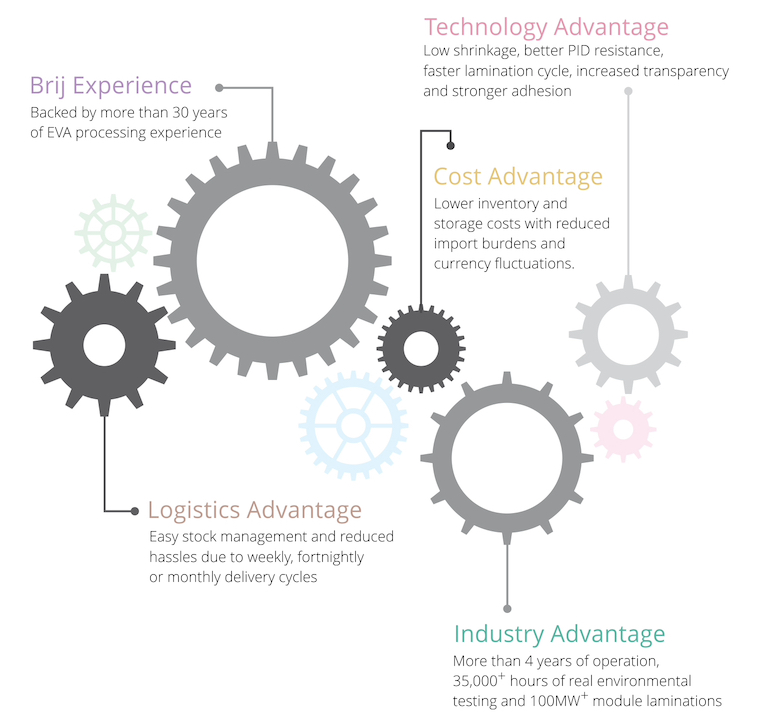

The Brij Advantage

With over 25,000+ hours of real environmental testing and over 100MW of module laminations, ‘Brij Advantage’ series of module encapsulation solutions have been serving the industry since 2011. Optimised for Indian conditions at its ultra modern & fully automated production facility, ‘Brij Encapsulants’ offer 1.) High transparency 2.) Better PID resistance 3.) Strong adhesion and 4.) Low shrinkage.

This results in lower failure rates, better performance and slower degradation during module lifetime, providing better overall return on investments. With separate quality assurance team performing regular in-line quality checks, Brij assures that your modules will last not for 25 years but for a lifetime

Head Office

New Delhi – 110034