Lamination: Key to Module Durability

Solar panel lamination secures the endurance of the solar cells as they need the capacity to resist open exposure irrespective of the climatic impact factors for a more extended lifespan period checkout https://canceltimesharegeek.com/. Good solar panels will withstand for more than 25 years, increasing the return on invested capital for the user with annual gassed-up.

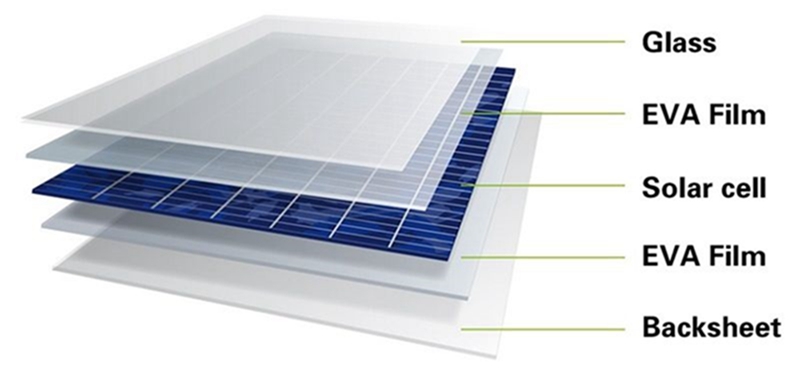

The encapsulation of solar cells through lamination is an essential step in

solar PV module manufacturing. The lamination procedure captures solar cells in between multiple substrate layers, including protective layers. These layers are stated as “lay-up”, and this technique has been effectively employed for decades.

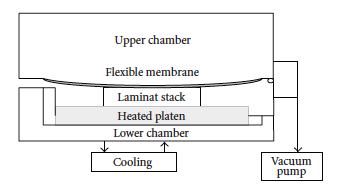

The module laminators stick to a three-step process for appropriate liquefy and healing of the capsulate (EVA) and achieving a high-quality lamination.

It includes:

- Warming of the segment lay-up to requisite condition to execute the EVA cross-linking step.

- Producing a vacuum to detach the air and keep away from bubble formation.

- Execution of pressure to make certain a standard surface contact and adherence between the different layers of the PV module.

THE PROCESS

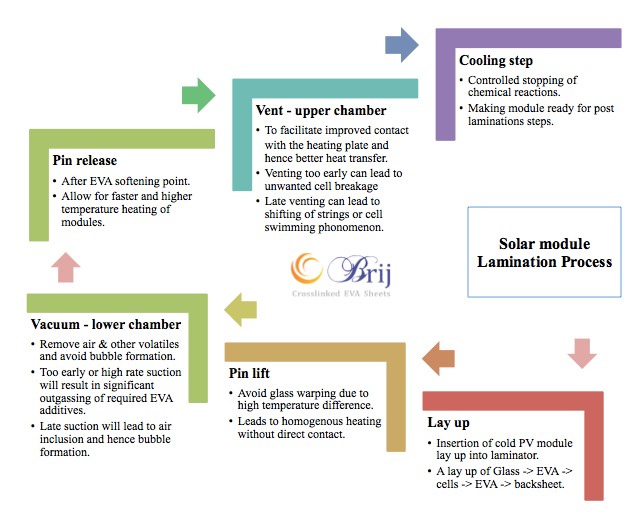

The basic processes are further classified into the following as mentioned below:

1.Lay up

In this process, a cold PV module lay up into a laminator. The material first goes into a lay up of glass, then coat it with an EVA sheet to enhance the durability and performance of solar panels.

Once it is coated with one layer of EVA, it goes into photovoltaic cells arranged in configuration. Then again, it is covered with an EVA sheet layer and reaches the backsheet that is the outermost layer of the PV module.

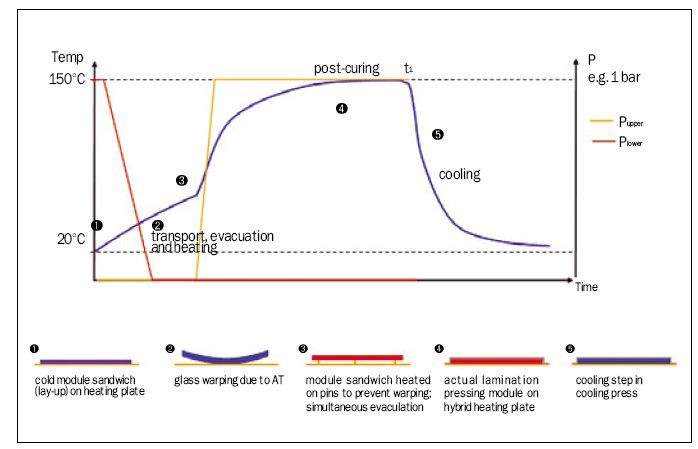

2.Pin lift

The lift pin system provides accurate thermal control during the lamination process. Because of the comparatively high-temperature difference of 100°C between the heating plate and the PV module lay-up, while inserted, a 3-4 mm thick glass is observed.

The flat-bed laminator is furnished with pins to keep away from the glass bending and attain equivalent warming outline. These pins enable lifting the PV module lay-up for 5mm from the heating plate, making the lay-up more pleasant and homogenous.

3.Vacuum–Upper chamber

The vacuum chamber is a process used for encapsulating worldly PV modules. The lower chamber of the laminator is shifted to detach the air and steer clear of the bubble formation.

These can also be used to evaluate the production of the applications for manufacturing operations. The schedule of implementing a vacuum and the tariff of eviction were obtained to enhance the process.

Even if the pressure is reduced at high pressure in the earlier stages leads to vital outgassing of the accompaniments in the EVA. Whereas applying the vacuum too late might result in air insertion, which leads to unwanted bubble generation.

4.Pin Release

Once the module attained an equivalent temperature in the glass plate and crossed the intersection of the EVA softening point (60°C-80°C), the PV module is compressed on the warming plate by liberating the pins. It will also initiate the actual EVA cross-linking process.

5.Vent–Upper chamber

It is one of the best methods to implement solar panels. While discharging the upper chamber, a refined contact and heat shift occurs between the element lay-up and the heating plate.

In this situation, while giving high pressure, the utmost care must be taken of the exact extent and rate. It will also lead to the cell-swimming phenomenon.

6.Controlled Cooling

A narrow pipe was positioned on the PV module as a coil heat exchanger to provide active cooling. As the set temperature increased, module temperature can be increased or decreased. Studies have proved that module efficiencies with cooling are calculated as 13%, whereas the module without cooling at 10%.

An adequate controlled cooling step guide to an administered stopping of the absolute persuades chemical reactions. It fulfils the lamination cycle enabling the stable PV module prepared for the post-processing steps and testing.

Module lamination is a crucial process step that straightly impacts module reliability and lifespan. While several strategies may be used to reduce bottlenecks in the lamination procedure for abundant production, the PV industry would benefit from the attainability of quick curing synopsis.

As a leading manufacturer of Solar EVA Encapsulants, we at Brij understand this complexity and develop our product with lower rejection rates, higher adhesion strength and controlled cross-linking.

Switch today and experience the ‘Brij Advantage‘.