Considerations for Selection of EVA Encapsulants

- Location

- New Delhi

- Pubished Year

- 2015

- Published

- Solar Quarter

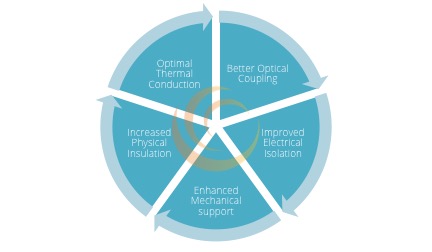

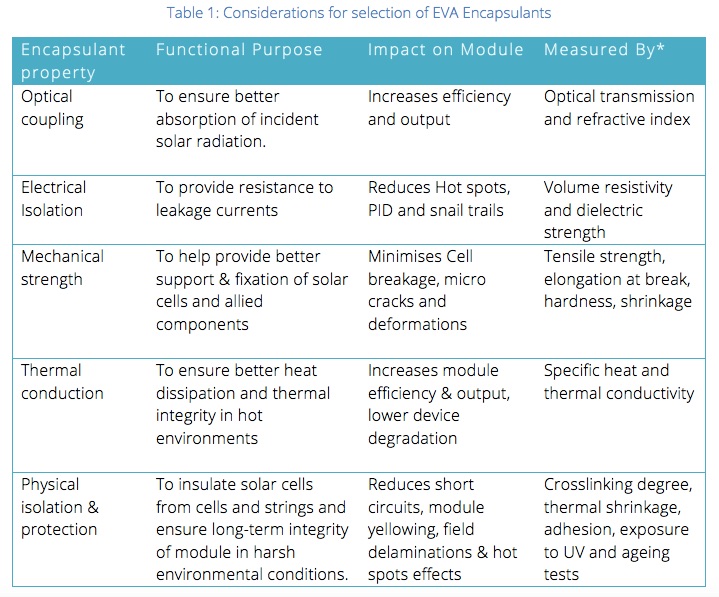

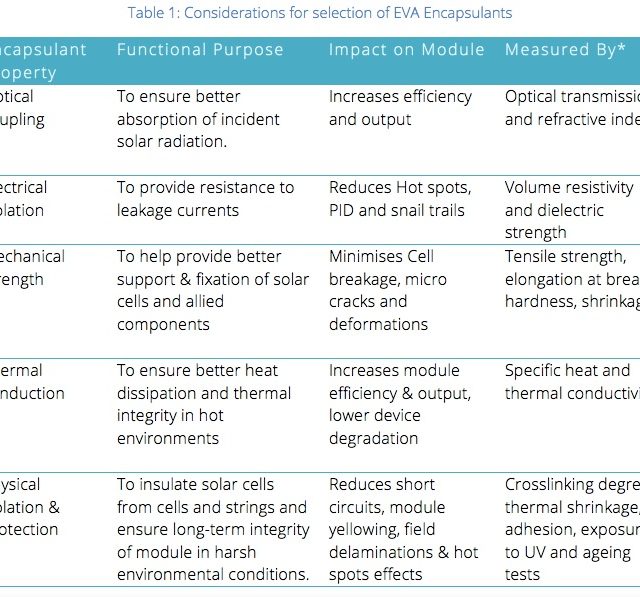

Since decades, photovoltaic modules have been encapsulated with crosslinked Ethylene Vinyl Acetate (EVA) sheets as they still provide the most optimal solution for packaging solar cells with the required degree of environmental protection. However apart from just long term protection, encapsulants serve multiple other purposes also. They physically hold module components in place, provide electrical insulation, reduce moisture ingress, optically couple superstrate materials (e.g., glass) to PV cells, protect components from mechanical stress and protect materials from corrosion.

To achieve this, encapsulants must adhere well to all surfaces, remain compliant, and transmit light after exposure to temperature, humidity, and UV radiation histories. All these and many others are discussed below in detail:

- Optical Coupling

- Electrical Isolation

- Mechanical Strength

- Thermal Conduction

- Physical Insulation & Protection

Front side EVA forms the mid layer between Glass and solar cells. Thus every lumen of incident light passes this layer before reaching the solar cells. EVA thus requires optimal refractive index in order to direct maximum light from the glass into the solar cells. Also since any light absorption would lead to reduced cell efficiencies and hence module performance, an encapsulant should also maximise light transmission to ensure better module efficiency.

Solar modules require good electrical isolation between the cell and other components to avoid leakage currents which can cause a variety of defects such as Potential Induced Degradation (PID), snail trails, corrosion of interconnects etc. (discussed in Brij whitepaper on ‘Field issues in crystalline solar PV modules’). Encapsulants with high electrical resistivity, dielectric strength as well as lower water absorption rate keep leakage currents to a minimum and prove advantageous for long life of modules.

Solar modules require good electrical isolation between the cell and other components to avoid leakage currents which can cause a variety of defects such as Potential Induced Degradation (PID), snail trails, corrosion of interconnects etc. (discussed in Brij whitepaper on ‘Field issues in crystalline solar PV modules’). Encapsulants with high electrical resistivity, dielectric strength as well as lower water absorption rate keep leakage currents to a minimum and prove advantageous for long life of modules.

PV modules can reach high operating temperatures (80°C-100°C) during operation. Without sufficient heat dissipation, the encapsulated solar cell can run at temperatures that are significantly higher than the ambient temperature reducing its performance and efficiency. By ensuring high thermal conduction, a quality encapsulant not only ensures low temperature operation of modules but also gives better efficiency and long-term performance.

A solar module comprises of electrically connected series of solar cells, all working in tandem to produce the desired output. By lowering movement of cells during processing and strongly adhering to cells and other components in field, EVA ensures both physical and electrical isolation between adjoining cells and busbars, preventing short circuits, localised heating and hot spots.

Access specialized SEO strategies tailored for rehab centers at rehab SEO, maximizing visibility and attracting more clients to support their journey towards recovery.