- Adhesion

- Crosslinking Ratio

- Dimensional Stability

Whitepapers

Product testing is a form of quality assurance in relation to product research and development. Although this process is considered as the most tedious and expensive stage of research and development; it is still imperative.

The standard tests for determination of quality of various module components and especialy EVA are vastly varied and sometimes ambiguous. However the following tests are generally used to define quality of the EVA encapsulant films.

Some or all of these tests can be performed on the shop floor on regular basis to ensure consistency:

- Adhesion

- Crosslinking Ratio

- Dimensional Stability

Adhesion of EVA to substrate is key to the longevity of a module throughout its operational lifetime. Low adhesion is a good indication of expired EVA or exposure to moisture during transit/storage or even improper laminating conditions. EN 1895 & ASTM D-1876 test standards can be followed to determine the peel strength accurately. Spring balance test is often used in the industry as quick test to validate the incoming material. Values between 75 N/cm and 125 N/cm can be used as a reference for quality control.

Gel content of EVA is a measure of degree of crosslinking of the polymer. Lower gel content indicates lower dgeree of crosslinking, which severely jeopardises the long term mechanical integrity of the module. ASTM D-2765 test standard can be followed to determine the gel content accurately. Variations of the same are often used to approximate the gel content values at shop floor level.

If encapsulant is not expired, lower gel content is generally due to lower crosslinking and hence inappropriate laminating conditions. Gel content levels of 70% and higher are recommended for longer lifetimes.

EVA films have an inherent tendency to shrink when heated at lamination temperatures, which if not controlled might lead to breakage of solar cells, mislaignment of strings, amongst other stability issues.

Shrinkage is generally caused due to process induced stresses during the manufacturing of EVA films however the rule ‘lower the shrinkage and better the encapsulant’ is not generally true due to a variety of other trade-offs. Globally, shrinkage levels of 2% or less are acceptable and are known to cause no laminating problems.

Product testing is a form of quality assurance in relation to product research and development. Although this process is considered as the most tedious and expensive stage of research and development; it is still imperative.

The standard tests for determination of quality of various module components and especialy EVA are vastly varied and sometimes ambiguous. However the following tests are generally used to define quality of the EVA encapsulant films.

Some or all of these tests can be performed on the shop floor on regular basis to ensure consistency:

- Adhesion

- Crosslinking Ratio

- Dimensional Stability

Adhesion of EVA to substrate is key to the longevity of a module throughout its operational lifetime. Low adhesion is a good indication of expired EVA or exposure to moisture during transit/storage or even improper laminating conditions. EN 1895 & ASTM D-1876 test standards can be followed to determine the peel strength accurately. Spring balance test is often used in the industry as quick test to validate the incoming material. Values between 75 N/cm and 125 N/cm can be used as a reference for quality control.

Gel content of EVA is a measure of degree of crosslinking of the polymer. Lower gel content indicates lower dgeree of crosslinking, which severely jeopardises the long term mechanical integrity of the module. ASTM D-2765 test standard can be followed to determine the gel content accurately. Variations of the same are often used to approximate the gel content values at shop floor level.

If encapsulant is not expired, lower gel content is generally due to lower crosslinking and hence inappropriate laminating conditions. Gel content levels of 70% and higher are recommended for longer lifetimes.

EVA films have an inherent tendency to shrink when heated at lamination temperatures, which if not controlled might lead to breakage of solar cells, mislaignment of strings, amongst other stability issues.

Shrinkage is generally caused due to process induced stresses during the manufacturing of EVA films however the rule ‘lower the shrinkage and better the encapsulant’ is not generally true due to a variety of other trade-offs. Globally, shrinkage levels of 2% or less are acceptable and are known to cause no laminating problems.

- Adhesion

- Crosslinking Ratio

- Dimensional Stability

- Adhesion

- Crosslinking Ratio

- Dimensional Stability

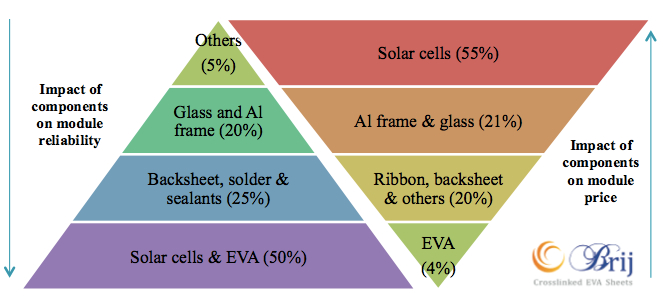

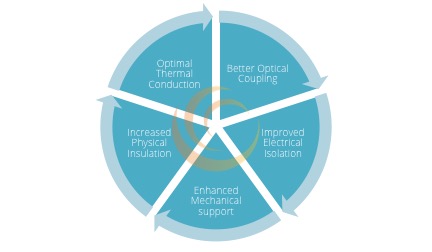

Since decades, photovoltaic modules have been encapsulated with crosslinked Ethylene Vinyl Acetate (EVA) sheets as they still provide the most optimal solution for packaging solar cells with the required degree of environmental protection.

Head Office

New Delhi – 110034